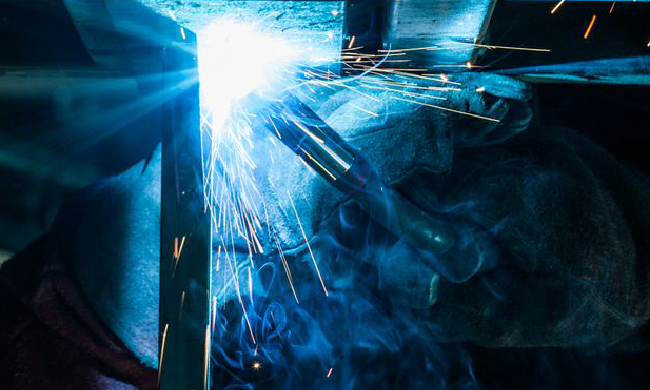

VTW’s welding department excels at fabricating assemblies and components, offering a wide range of welding techniques from MIG, TIG, butt welding, and spot welding.

MIG/TIG welding machines and our robotic welding system allows Versatility Tool Works and Manufacturing's ultra-precise welding operations including a large number of enclosure products with welded corners. Our innovative machinery can sense distance and perform instantaneous auto corrections, promising high-quality products with quick turnaround times. VTW’s advanced welding technology can be used to create large, complex shapes with multiple facets to make enclosures and component parts in any configuration.

Quality MIG / TIG Welding

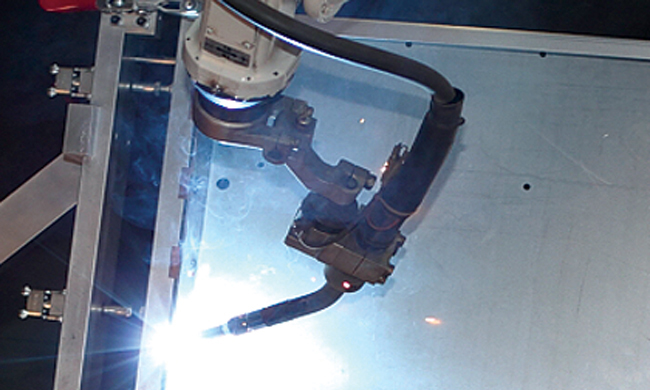

Robotic Spot Welding

Versatility Tool Works and Manufacturing also utilizes the latest robotic welding techniques to deliver high quality, repeatable and esthetically clean welds.

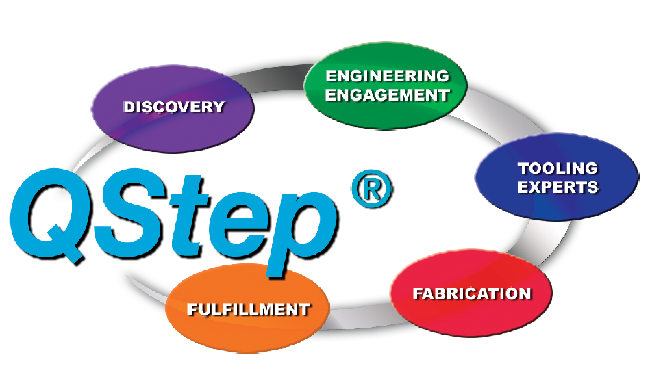

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.