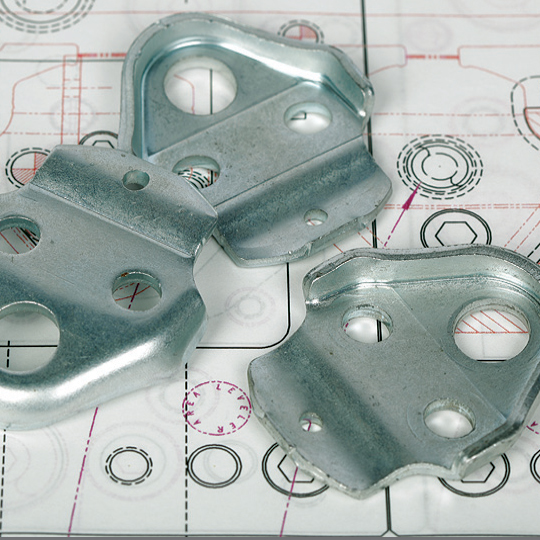

Convey Clamp Stamping

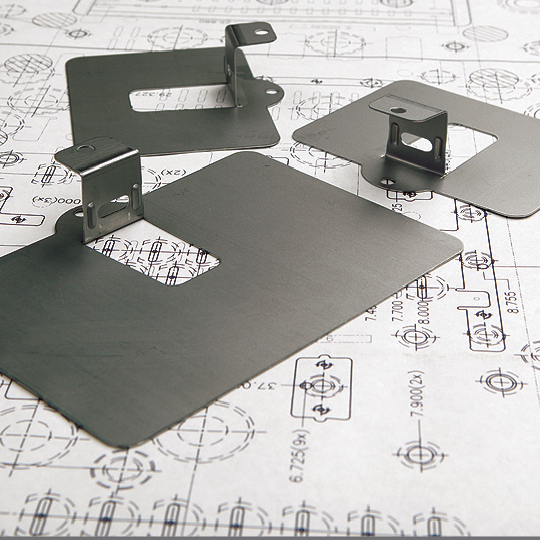

Follower Block Stamping

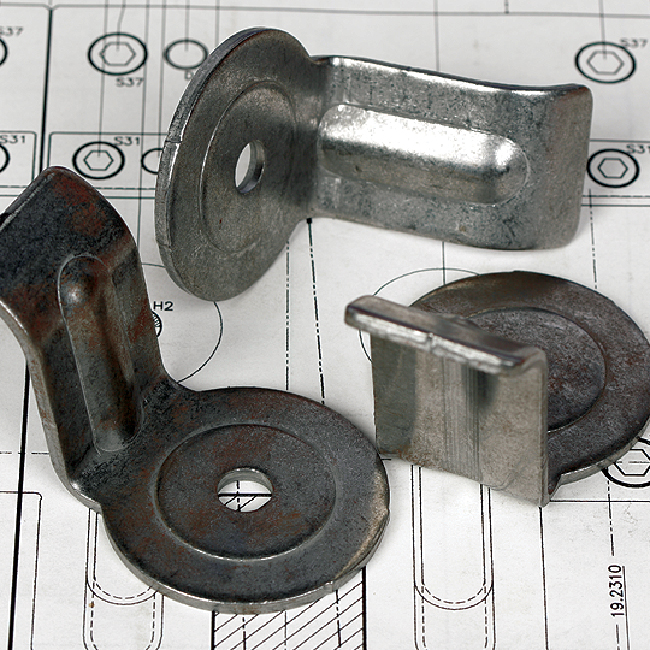

Stair Bracket Stamping

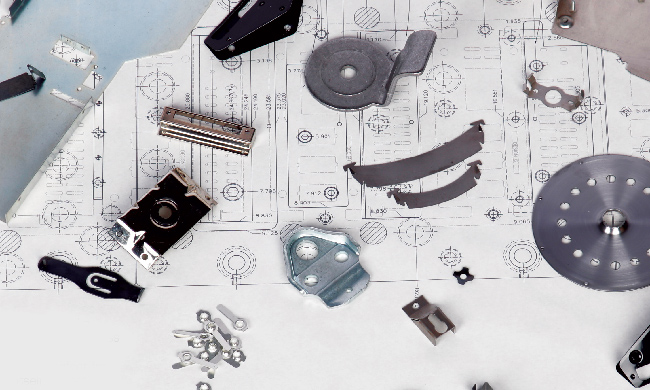

Fastener Clip Stamping

As a leader in precision stamping, Versatility Tool Works and Manufacturing have the equipment, personnel, capacity, and versatility to handle any job scale on your part, component or assembly.

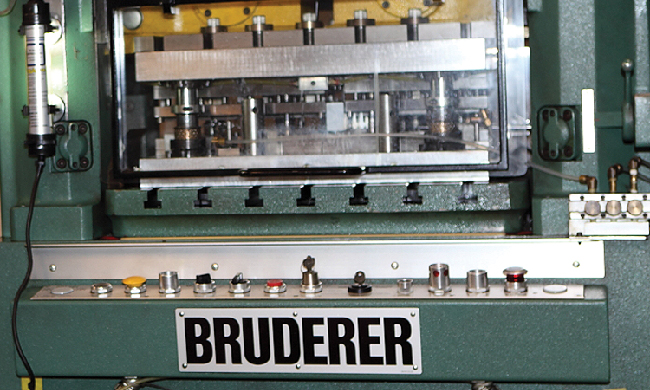

We specialize in punch press, transfer die, and progressive stamping of tight tolerances, high-precision stampings. Close tolerance die stamping is critical for achieving the tight uniformity necessary for modern manufacturing. The metal stamping process utilizes progressive compound dies, making it possible to accomplish more than one procedure at the same time.

Modern metal stamping technology makes use of electronic sensors to protect the die and regulate the stamping process. VTW engineers also utilize advanced CAD and 3D software packages to optimize, stage, and design tooling, for economical production of precision parts.

VIDEO: VTW's Bruderer Machinery

Punch Press

High Volume Fastener Stamping

Engineer Tests and Checks Programming

Minster P2-30-30 Punch Press Stamped Parts Versatility engineers have embedded numerous sensors inside the die. The sensors are tied to a computer which monitors all of the critical process parameters with each press stroke. The die tooling is constructed from carbide materials and operates at almost 10 press strokes per second. Versatility has produced more than 2 billion pieces with zero quality defects.

VIDEO: VTW's Minster P2-30-30

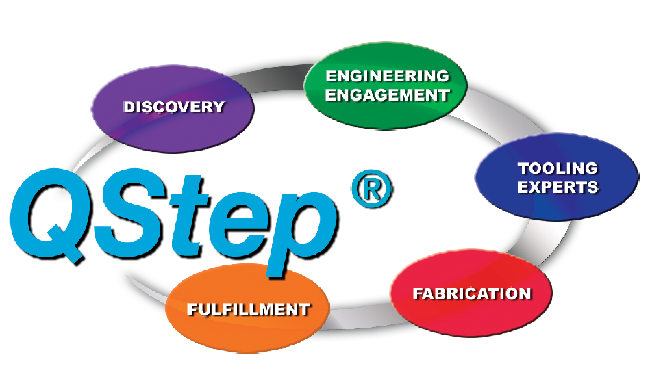

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.