VTW’s sheet metal forming capabilities are known around Chicagoland and the Midwest for fabricating precision formed steel products and providing manufacturing excellence through innovation and technically advanced equipment.

The HG ATC - Series Hybrid Bending Press Brake is the perfect match for variable lot sizes, complex tool setups and allows VTW to introduce rush jobs seamlessly by loading the setup in less than 3 minutes. BiS - Bend Indicator Sensor automatically detects and compensates for material spring back, automatically adjusts for material thickness and hardness. This hybrid high precision, high-speed press brake lets VTW offer unmatched bending control and accuracy.

VIDEO: VTW's HG ATC - Series Hybrid Bending Machine

Precision Press Brake Forming Machine with Automatic Tool Changer

VTW cuts metal and forms to specifications with our AMADA press brakes and other extensive metal forming equipment and, along with VTW’s highly experienced personnel, can produce any variety of shapes including angles, “U” shapes, hat shapes, multiple bend shapes, “C” shapes, and off sets. .

Precision metal forming is a vital part of the metal manufacturing process. No matter how complicated the bends or combinations of bends at varying angular degrees, VTW has the equipment to streamline the process and lower part costs.

Press Brake Forming

We can manufacture parts and blanks based on nearly any concept, drawing, or physical example to your design specifications. We can create the most complicated and precise shapes out of many different materials because of our technology, advanced equipment, and experienced staff.

VTW's Modern Equipment and Engineering Team Fabricate Precision Metal Parts and Assemblies Quickly

Since we have the most modern equipment to punch, form, perforate, weld, laser cut, custom tool, and stamp metal, VTW can fabricate metal parts and components quickly, to very high quality, and to your unique specifications.

Precision Metal Forming Assures Very High-Quality Metal Parts and Components

Saves You Development and Processing Time

Fast Delivery

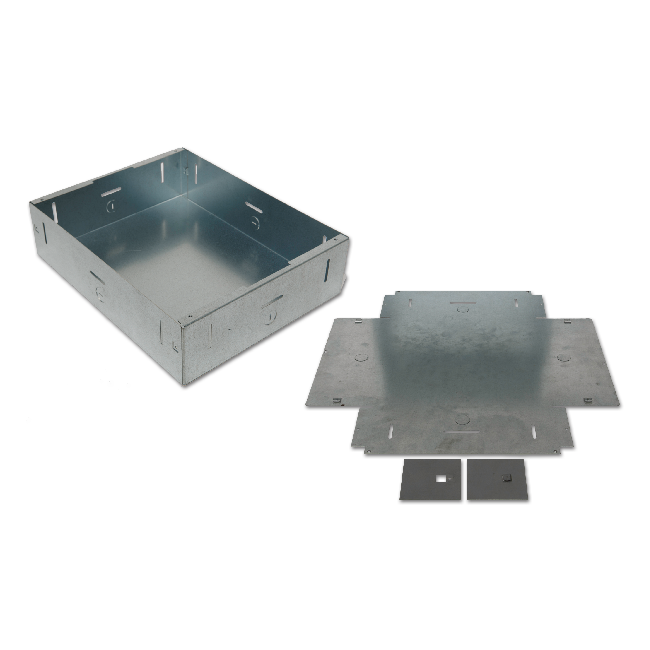

Simplified Enclosure

650x650.png)

Fast Turnaround

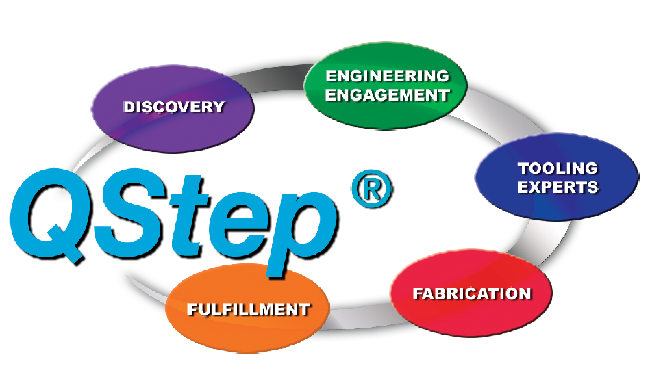

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.