Versatility invests in state of the art, high-tech equipment that makes a significant difference with precision sheet metal fabrication. It means that thin gauged metal can be easily shaped, formed, pressed, welded, punched, and precision cut in any way to meet your manufacturing requirements. These machines play an integral role in our ability to dramatically reduce your Time to Market and Overall Turnaround Time. Versatility depends upon sheet metal fabrication technology to help meet the fast-paced manufacturing demands of our customers.

Versatility Tool Works and Manufacturing’s HG ATC - SERIES Hybrid bending machine is the ideal solution for variable lot sizes and complex tool layouts. The automatic Tool Changer can load the most complex tool layout within minutes. For precision sheet metal forming, the integrated bend sensor guarantees consistent bend angle accuracy for ZERO DEFECTS production.

The HG HTC Hybrid Bending Machine allows us to:

The combination of the laser and turret press in a single sheet metal fabrication machine increases our manufacturing productivity, reduces costs, and eliminates many costly secondary operations during fabrication. Programming time is saved, special tooling can be eliminated, set up time is less, and custom parts can be finished in record time.

VTW's LC 2012C1NT is an automated, seamless integration process of laser and punching operations to materials up to 1/4" thick. The machine's precision sheet metal fabrication capabilities not only provide a fast track from print to product but also eliminate many costly secondary operations.

Our EM 2510NT servo-drive CNC punch press has even more capabilities with the addition of the MP 1225NJ auto-robotic load/unload system.

With automated loading and unloading of the turret punch press, VTW can dramatically boost turret press productivity, allowing us to deliver shorter lead times, improved quality, and lower cost.

This allows unmanned operation of the punch press and enables the machine to be run during the day, during breaks and lunches, and after hours.

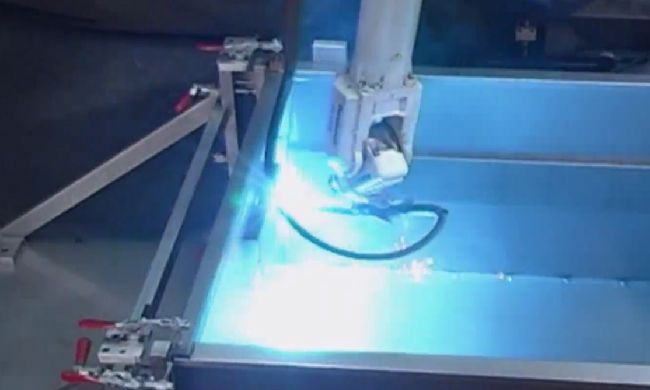

VTW’s Robotic Welding Cell produces consistent, high-quality welds with minimal surface distortion. Versatility Tool has successfully integrated robotic systems to significantly boost productivity and quality in our manufacturing process.

VTW’s Epilog Fiber Laser can:

Engraving Barcodes

Engrave or Etch a Logo on Parts

Mark Product Identification

Serialization

Engrave or Etch Medical Part Marking

Photo Etching

Product Marking

Nameplates

Rating Plates

Industrial Etching And much more!