Collaborative Robot Supercharges VTW’s Assembly Line

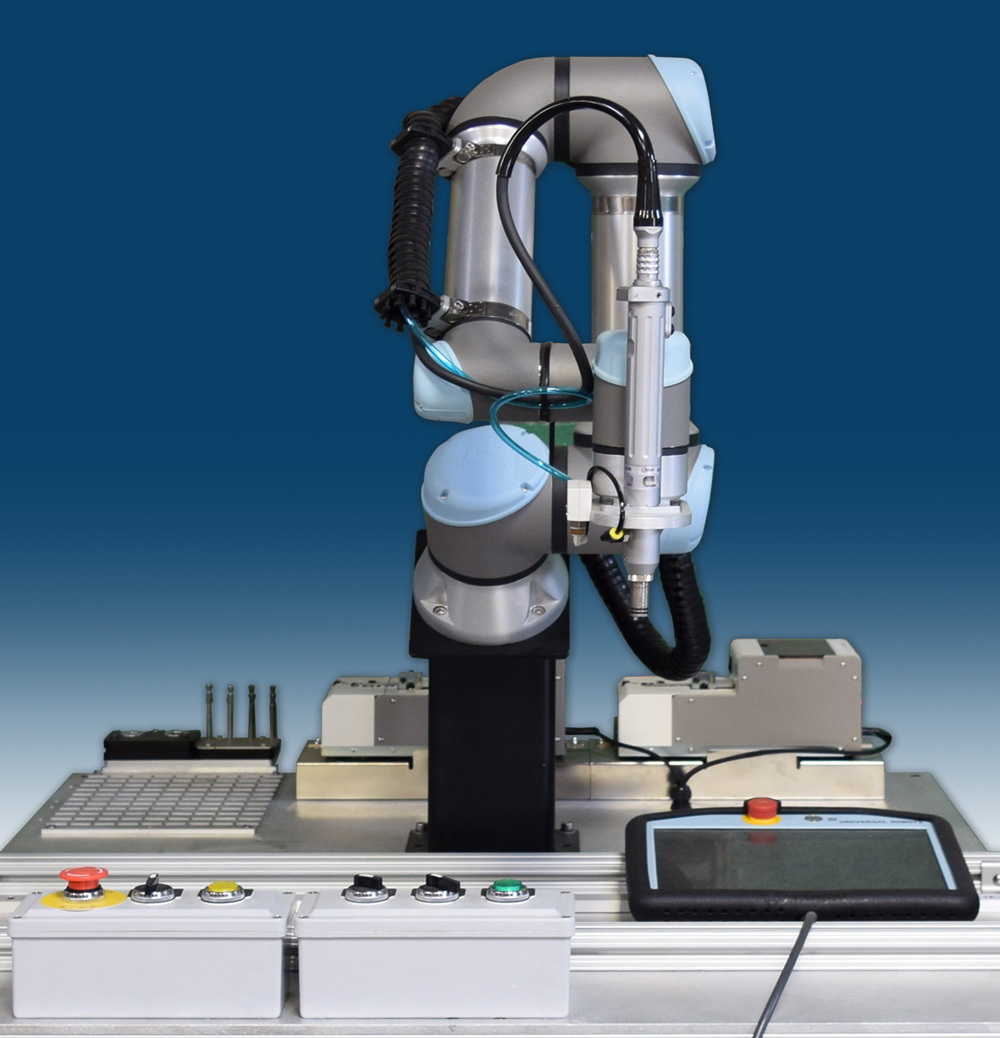

We are excited to announce that Versatility Tool has added a new Collaborative Robot to our electro-mechanical assembly line!

VTW's new COBOT takes over the labor intensive tasks on our equipment production line. Besides relieving workers of physical burdens, the collaborative robot also improves the fit and finish of your products by raising levels of precision and consistency in production.

The cobot works around the clock with precision and minimal errors.

The e-Series Cobot ensures that every screw and component in our manufacturing production can be installed with perfect positioning and accuracy and helps us lower overall assembly costs.

What is a Collaborative Robot?

Collaborative robots, also called Cobots, are robots designed to work safely alongside people within a shared space. Unlike their larger industrial robot cousins, Cobots do not need to be isolated within a cage because they are designed to stop safety when colliding with a fellow worker. Cobots are aimed at helping humans do their jobs better, not replacing them. They complement and augment what humans do, making workers more effective and efficient. To qualify as a Cobot, a robot must conform to strict International Safety Standards as outlined in ISO Specification 10218.

How are Cobots different from other Industrial Robots?

Besides the safety considerations, Cobots are smaller, more adaptable, and considerably more flexible than traditional industrial robots. Cobots are also easier to program. Rather than writing G-code, cobots are programmed by humans manipulating the arms and training by example. When the Cobot is moved around, it remembers the steps and then repeats those steps, optimizing them to achieve progressively better outcomes.

What does all this mean for Versatility Tool Work’s customers?

Cobots are intuitive, easy to use, and game changers in the manufacturing environment. Benefits for VTW’s customers include: