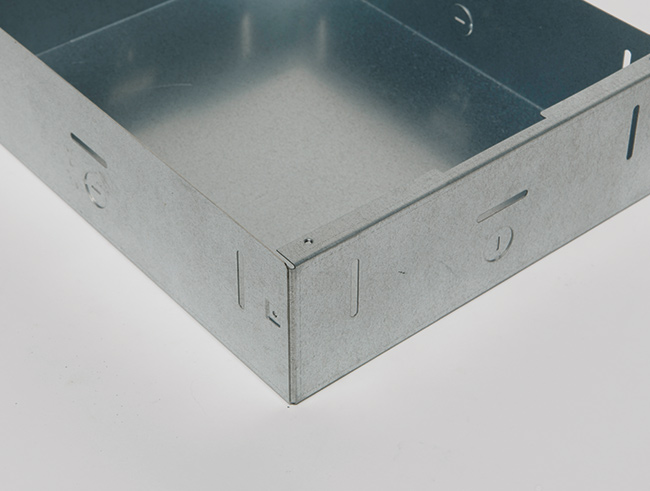

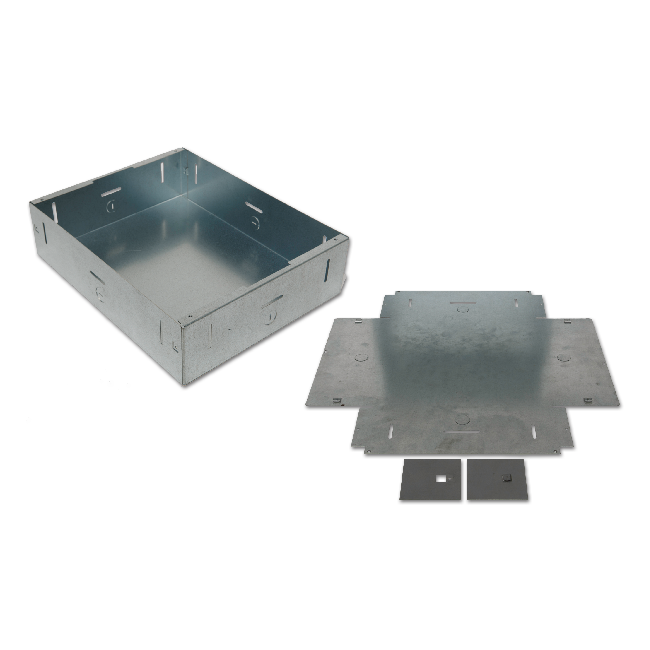

VTW developed a snap together enclosure design that did not require painting, welding or hardware insertion. The improved design was fabricated from galvanized material and added an innovative shear form feature.

The new enclosure is formed in the Press Brake and snaps together, eliminating the entire welding secondary operation. Utilizing VTW's advanced manufacturing capabilities, holes were extruded and tapped during the blanking process, eliminating hardware insertion (PEM Fasteners), another secondary operation.

The new enclosure met all of AND's exact design requirements while significantly reducing cost, delivery time, and improving quality.

CLICK HERE for CASE STUDY DETAILS PDF.

VIDEO: Advanced Network Devices Testimonial