INNOVATIVE ENGINEERING

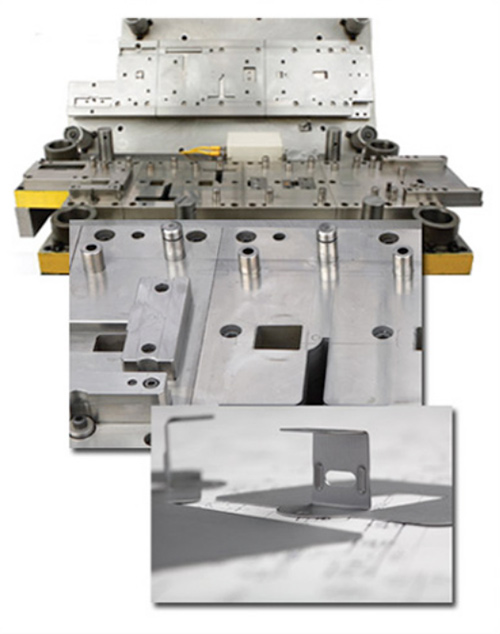

Versatility’s engineers and craftsmen build progressive stamping tools which deliver quality components using the most efficient methods possible.

The pictured tool features pneumatically driven form blocks which move during the press stroke, allowing the stock to be fed in the most cost-effective manner. The entire process is controlled by a computer which communicates with the press control, ensuring that the blocks move at the exact moment necessary to clear the forms.

Innovative use of advanced technology allows Versatility’s engineers and toolmakers to deliver solutions to our customer’s toughest problems.