Using technically advanced Servo Turret Punch capabilities, along with our other punches, VTW is capable of precision and speed to punch and fabricate your products. VTW’s CNC sheet metal punching turrets can process the most intricate formed features, perforations, and patterns with high-speed precision. Sheet metal punching is the most efficient way to produce precision fabricated metal products with many holes.

VIDEO: See VTW Vipros 255 Turret Press in Operation.

Turret Press: Amada Vipros 255

Our sheet metal punching machine can also form countersinks, embossments, extrusions, and louvers. Perfect for customized metal products with perforated hole patterns, electrical knock-outs, part number stamps, and countersunk holes.

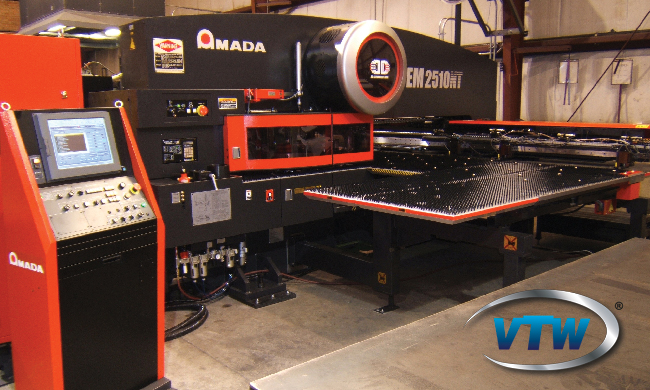

VIDEO: See VTW EM 2510NY Turret Press in Operation.

Turret Press :Amada EM 2510NT with MP 1225NJ

The combination of the laser and turret press in a single machine increases our productivity, reduces costs, and eliminates many costly secondary operations. Programming time is saved, special tooling can be eliminated, set up time is less, and your custom parts can be finished in record time. These machines play an integral role in our ability to turn prototypes around quickly.

Laser-Turret Press: Amada LC 2012C1NT with MP 2512C1

.jpg)

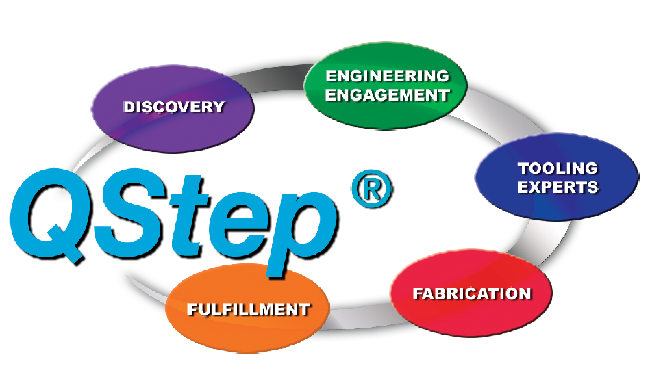

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.