With the latest technology equipment and highly qualified employees, VTW offers precision cutting from prototype through production in 2D (two dimensional) flat parts and customizing 3D (three dimensional) pre-fabricated components. Metal laser cutting, tolerances on location, radius and size can be repeatedly held at high volumes over extended periods of time. Laser cutting also limits material warping, as lasers have a small heat affected zone. With this caliber of precision and accuracy, Versatility Tool and manufacturing can reduce or eliminate additional steps in the manufacturing process, such as adding weld, grinding, flattening, or machining.

The versatile C1 is an automated, "lights out" blanking system which provides Versatility Tool Works with a seamless integration process of laser and punching operations of materials up to 1/4" thick. Innovative features include integrated hole tapping; die lift stations to minimize scratching during forming; an automated parts remover; and an automated sheet loading system. The new machine's capabilities not only provide a fast track from print to product but also eliminate many costly secondary operations.

VIDEO: See VTW's EM2510 MT Punch-Laser Combination in action.

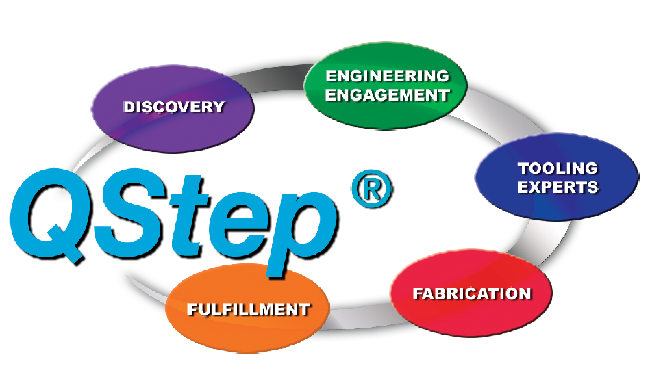

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.