Versatility Tool Works and Manufacturing offers Fiber Laser Barcode Engraving and Serializing, Logo, Tool and Part Identification, Logo Engraving and Medical Markings on parts and assemblies.

For High-Quality Laser Marking Solutions, Call 1-866-382-0482 to speak to a VTW Engineer or Project Manager Today!

VTW investment in the FUSION M2 32 Fiber Laser System means Versatility Tool Works and Manufacturing can offer:

• Highest Engraving Resolution

• Fastest Engraving Speeds

• Highest Contrast Grayscale Engraving

Laser Etching: FUSION M2 32 Fiber Laser

Etching logos directly on the part guarantees that our customers brand will always be immediately identifiable by his customer. Printed labels can be taken off the product, but an etched logo will be permanently marked on the product.

VTW's fiber laser can etch barcodes and serial numbers directly on parts, tools or assemblies providing a very high-quality mark that is easily read by barcode scanners. Choose between one-dimensional codes, UPC codes, data matrix or any other type of code.

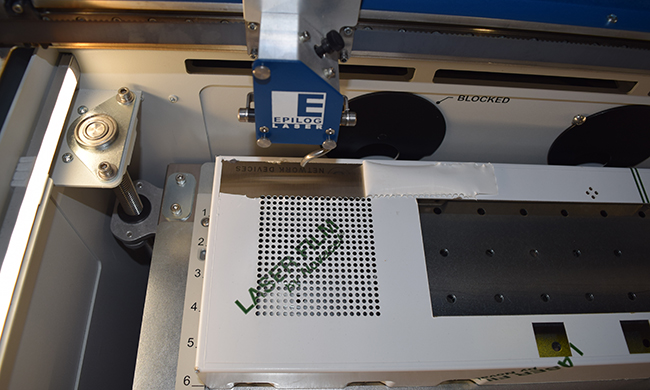

EPILOG Laser Marking Product Branding on Fabricated Housing and Chassis

Annealing Mark on 304 Brushed #4 Finished Stainless Steel

Ablation: The process of ablation is the removal from the surface of an object by vaporization. You’ll often hear of this process associated with etching an anodized material.

Ablation: The process of ablation is the removal from the surface of an object by vaporization. You’ll often hear of this process associated with etching an anodized material.

Annealing: This is the process of heating steel to a high temperature, creating a permanent oxide layer on the surface. The mark that results is a high-contrast mark created without changing the surface finish of the metal.

Annealing: This is the process of heating steel to a high temperature, creating a permanent oxide layer on the surface. The mark that results is a high-contrast mark created without changing the surface finish of the metal.

Color Changing: With some plastics, the laser radiation penetrates the plastic and is absorbed by the color pigments of the plastic. The pigments are chemically modified, resulting in a color change in the surface, without damaging the surface.

Color Changing: With some plastics, the laser radiation penetrates the plastic and is absorbed by the color pigments of the plastic. The pigments are chemically modified, resulting in a color change in the surface, without damaging the surface.

Engraving: The material is vaporized by the laser beam. The result is often a cone-shaped indentation due to the shape of the laser beam.

Engraving: The material is vaporized by the laser beam. The result is often a cone-shaped indentation due to the shape of the laser beam.

Foaming: Most commonly seen with plastics and sometimes stainless steel, foaming is when melting of the material occurs, producing gas bubbles that get trapped as the target material cools, producing an elevated result.

Foaming: Most commonly seen with plastics and sometimes stainless steel, foaming is when melting of the material occurs, producing gas bubbles that get trapped as the target material cools, producing an elevated result.

VIDEO: EPILOG Fiber Laser Video Demo.

Many other material options are available, please call and speak to an engineer!

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.

VTW's Qstep® Process assures quality fabrication, lowers manufacturing costs and allows quick turnaround on every project. READ MORE.