Versatility features today’s newest technologies available in manufacturing processes and continues to streamline our custom design work and automation. VTW can integrate more secondary options into one continuous process, thereby saving time, labor, and cutting costs that are passed onto our customers.

.jpg)

Quality is integral to the manufacturing process at Versatility Tool Works. Versatility's stamping tools use embedded sensors to monitor critical process parameters. This process monitoring together with VQS™, the Versatility Quality System, forms a powerful tool which enables us to deliver defect-free components to the customer. Uncompromisingly Quality Trained production employees, the latest high-tech fabricating machinery, and VQS - the Versatility Quality System - combine to produce components and assemblies of the highest integrity.

VTW’s equipment and facilities allow us to do medium or large production runs on precision sheet metal parts and assemblies. We specialize in understanding what each company wants, forming it to meet specifications and meeting delivery deadlines so that you can keep your production lines running. Since the quality of any product is based on the quality of the components, our fabricated metal parts and assemblies will ensure the best results for your final product.

_650x390(1).jpg)

Versatility Tool Works produces a consistent diverse lineup of parts, assemblies, enclosures, and complete products. At VTW, skilled craftsmen consistently produce dynamic parts under time-sensitive deliveries. Our dedication to the Power of Precision means we can fabricate and manufacture consistently with NO DEFECTS. Using program controlled fastener insertion, CNC Turret Punching, laser cutting and robotic welding, Versatility Tool Works and Manufacturing can fabricate your part, build a whole assembly or manufacture a complete product consistently with perfect quality.

We believe in and have proven that a project will be a success when we work closely with our customers throughout a project, from design to delivery. We provide you with direct access to years of experience, advanced engineering, and technical innovation. The finished result is precision quality, lower costs and complete satisfaction of your project.

Technology and innovation can't deliver results without experienced people. Our employees, a highly-trained team of engineers, craftsmen, and production personnel, each average over 25 years of service with Versatility Tool Works and Manufacturing. Working within a lean manufacturing culture which fosters teamwork and accountability, they share VTW’s passion to deliver metal fabrication results beyond the customers' expectations.

The QStep collaboration process engages the customer from project conception through ongoing fulfillment operations. The process has a demonstrated history of adding value to our customer relationships by positively impacting quality, cost, product performance, delivery and lead time. The QStep Process, when combined with Versatility’s Tool Work’s engineering expertise, cutting-edge design, and manufacturing technology, provides each of our customers a clear competitive advantage.

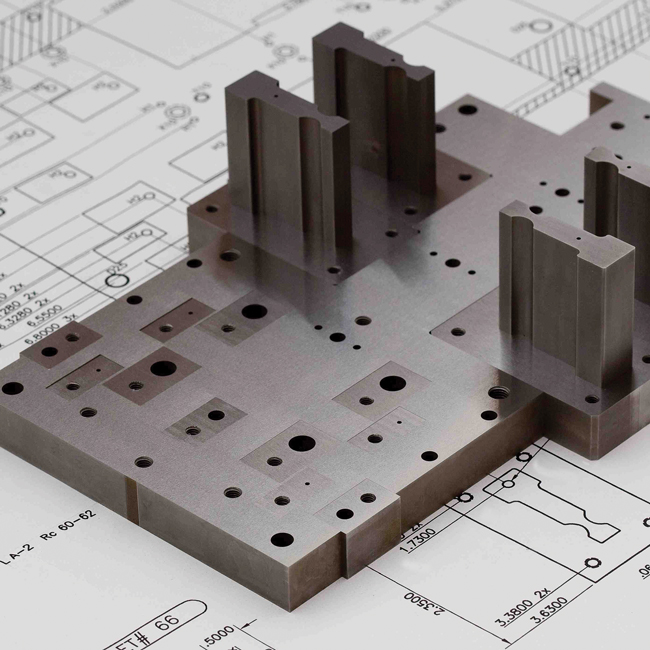

One of the biggest factors in reducing lead-time is our ability to design and build our tooling in-house. This level of speed and precision allows for fast production and enables Versatility Tool Works and Manufacturing to provide customers with close tolerances and superior surface finishes resulting in the highest quality parts possible.

Tool and Fixture Fabrication Inhouse

VTW also depends upon technology to help meet the fast-paced demands of our customers. Our LC 2021C1 and EM 2510NT dramatically boost productivity, allowing us to deliver shorter lead times, improved quality, and lower cost.

More on Fabrication Equipment

CNC Turret Punching

Automated Manufacturing

![]()

Robotic Welding

Automated Manufacturing